A conveyor’s specific function, however, varies greatly according to the type of materials it is designed to transport. For example, some industrial conveyors are powered by electric motors, while others work completely without electricity, and require an operator to keep the system running. Furthermore, some systems are portable and may be broken down and reassembled quickly and easily. Read More…

At Interroll Atlanta LLC, we are dedicated to advancing the efficiency and performance of material handling operations through our innovative conveyor solutions. As part of a global organization with a strong reputation for engineering excellence, we focus on delivering systems that meet the highest standards of reliability and flexibility.

At Pack Air Inc., we help manufacturers design and build innovative custom conveyors in the United States and Canada. Our specialty resides in creating custom conveyor solutions and product handling devices that help solve conveying problems. We don’t try to force pre-made conveyors in a box. Rather, we let the box define the solution so that your conveyors fit right the first time.

At Akona Process Solutions, we take pride in designing and manufacturing conveyor systems that bring efficiency, reliability, and innovation to material handling. Our team understands the importance of precision, durability, and streamlined operation, so we engineer our conveyors to meet the diverse needs of industries ranging from manufacturing and processing to packaging and distribution.

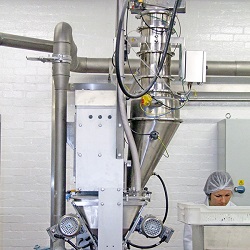

We are Volkmann, Inc., and we specialize in designing and delivering advanced conveyor solutions that move materials efficiently, cleanly, and safely through demanding industrial environments. Our focus is on high-performance conveying systems engineered to handle powders, granules, bulk solids, and other challenging materials where precision, hygiene, and reliability matter most.

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

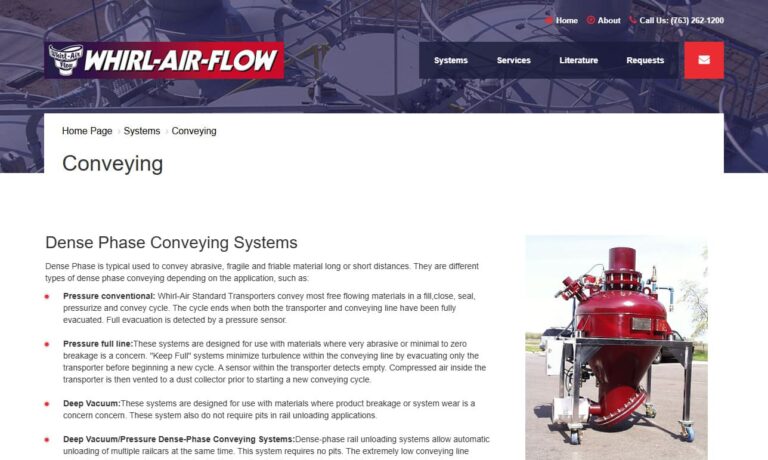

Whirl-Air-Flow has been specializing in the design, development and fabrication of pneumatic conveying systems since 1946. Our vast experience in dense and dilute phase conveying systems spans across a broad range of industries. Whirl-Air-Flow has over 55 years of specializing in dense and dilute phase conveying systems, blending systems, bag unloading systems, central vacuum systems, process...

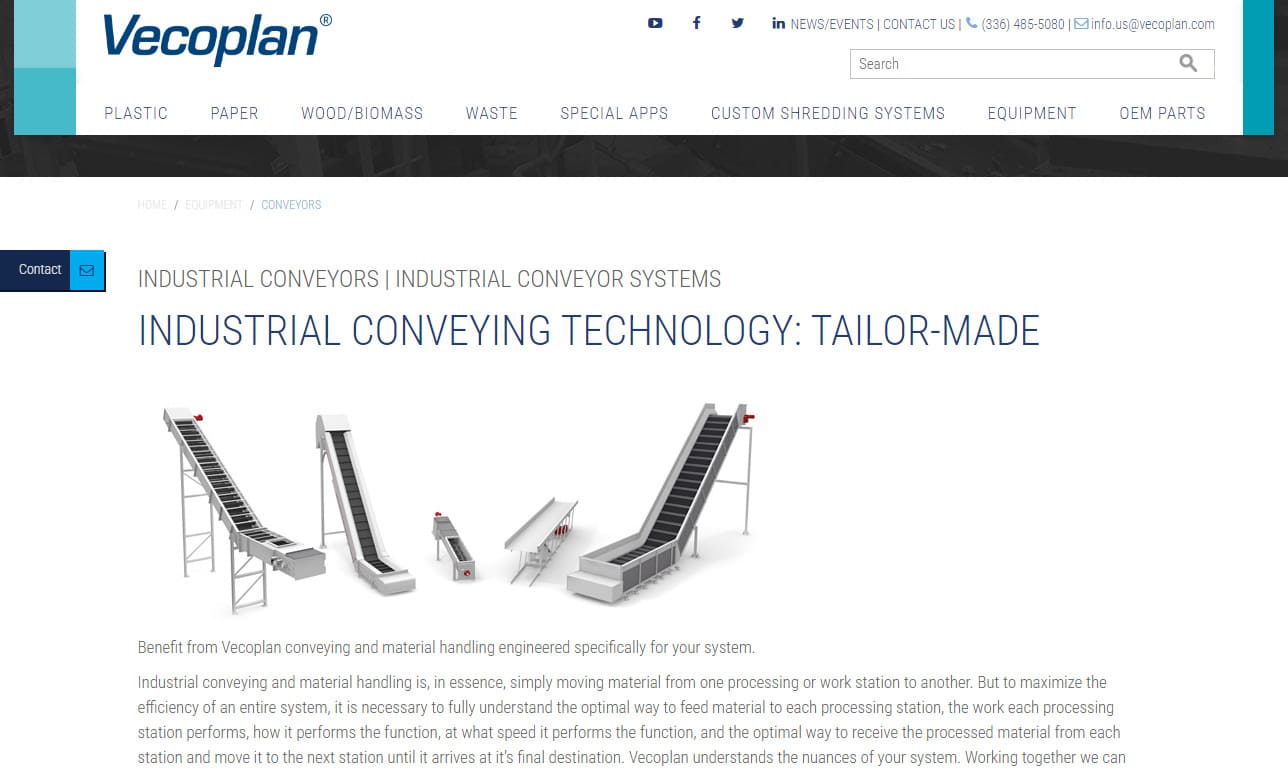

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

We are IEDCO, and we specialize in the design, manufacturing, and integration of conveyor systems built to move products efficiently, safely, and reliably through demanding industrial environments. Our work centers on creating conveyor solutions that are tailored to each operation, whether the application involves assembly lines, packaging processes, warehousing, material handling, or complex...

Since 1977, Conveyor Eng. & Mfg. has been a leader in the manufacture of stainless steel screw conveyors and conveyor components (bearings, flighting, hangers, screws, troughs, etc.). We serve a wide variety of industries including wet corn milling, food, sugar, ethanol and chemical. Contact us to learn more about our conveyor systems. We are available to answer any of your questions, feel free...

Automated Flexible Conveyor, Inc. (AFC) is a trusted leader in the design and manufacturing of high-quality conveyor systems tailored to meet the unique needs of diverse industries. With decades of experience, we take pride in offering innovative, reliable, and efficient solutions that optimize material handling processes.

At Liberty Conveyor, we are dedicated to delivering dependable conveyor systems that enhance efficiency and streamline operations across a wide range of industries. With years of expertise in conveyor technology, we design and manufacture solutions that are tailored to meet the demands of manufacturing facilities, warehouses, distribution centers, and specialized production environments.

At Transcon Conveyor, we take pride in designing and manufacturing conveyor systems that deliver lasting performance and reliability for even the most demanding industrial applications. With decades of experience in the field, we have built a reputation for engineering heavy-duty, custom-built conveyors that meet the unique needs of our customers across diverse industries.

At FATA Automation, we specialize in creating advanced conveyor systems and material handling solutions that help manufacturers and distributors streamline their operations and achieve higher levels of efficiency. We design, engineer, and manufacture conveyors that are customized to meet the demands of complex production lines, high-volume distribution centers, and intricate assembly environments.

More Industrial Conveyor Manufacturers

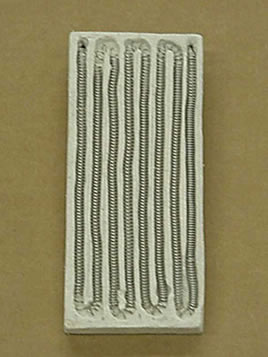

Two types of well-known industrial conveyors are belt conveyors and auger conveyors. Belt conveyor systems function using a rubberized belt that is wrapped around a series of rollers, some of which are connected to a motor that turns the rollers. After the motor turns the rollers, the rollers move the belt. Said belt, which is sometimes replaced with a metal chain belt or a plastic belt, must be tensioned properly in order to make sure it runs smoothly. If not, the belt may get caught on one or more components within the system. The next common industrial conveyor, the auger conveyor, features a large screw blade or auger that is contained within the system, usually inside a tube.

As the auger conveyor turns, those contents in the conveyor are propelled forward along the length of the system. Contents of an auger conveyor are usually some form of fine particulate, grain or semi-solid material. These materials include: wood waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal and municipal solid waste. This system requires that the belt be laid flat or at a slight angle only in a straight line, because the auger or screw itself must be straight.

Some industrial conveyors are required to run around corners or in other non-linear fashions. These industrial conveyors usually operate using a drag chain system. In this case, the conveyor contains a long cable or chain to which discs are attached. The cable or chain will pull the discs through the chamber where, in between each disc, material is loaded and pulled along through the system. In this system, there is little or no clearance between the discs and the side walls of the chamber, which prevents material from backsliding. For this reason, discs must be made from a durable material that will not succumb to friction. Consumer standard and custom options for industrial conveyors are nearly endless and those that are well-chosen and well-maintained will no doubt serve their purpose well for many years.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches